ErP 2020: Nicotra Gebhardt prezinta noile ventilatoare de acoperis

The ErP Directive (Energy-related Products) also requires ever higher performance at lower energy consumption for roof fans.Whilst the majority of the industry here is just looking to more cost-efficient motors, we at Nicotra Gebhardt are looking at the whole picture.The impeller and housing design are specifically included in our concept in all our models.The new generation of fans thus also exceeds all the future requirements of the ErP Directive which is to be implemented in stages.The developers from Waldenburg (D) now rely entirely on asynchronous internal rotor motors available worldwide.These are systemically superior to traditional fans with external rotor motors due to more advantageous flow conditions.The result is increased energy efficiency.Maintenance and user friendliness is becoming increasingly significant.If a standard motor malfunctions, it can be easily replaced with an energy-saving motor of the same size in a few, simple steps.

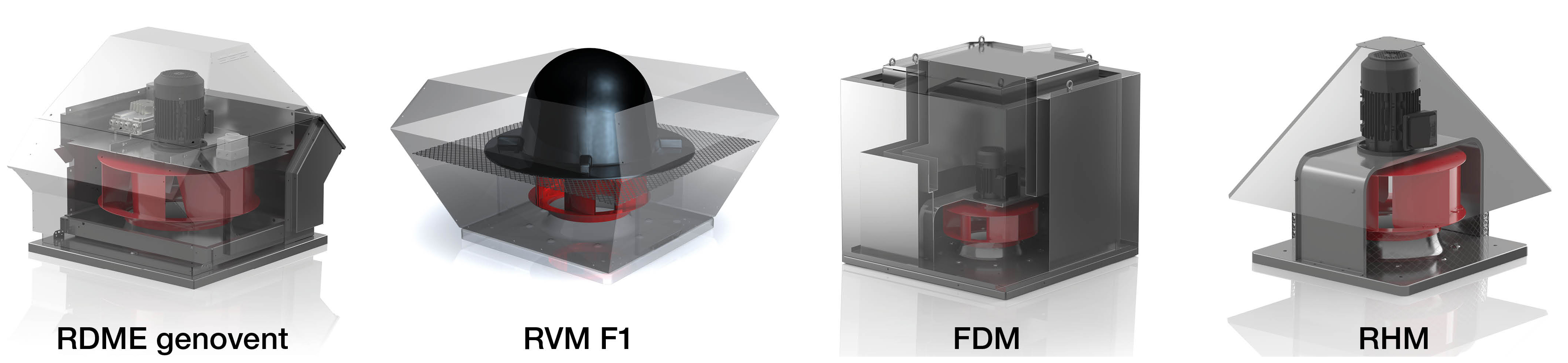

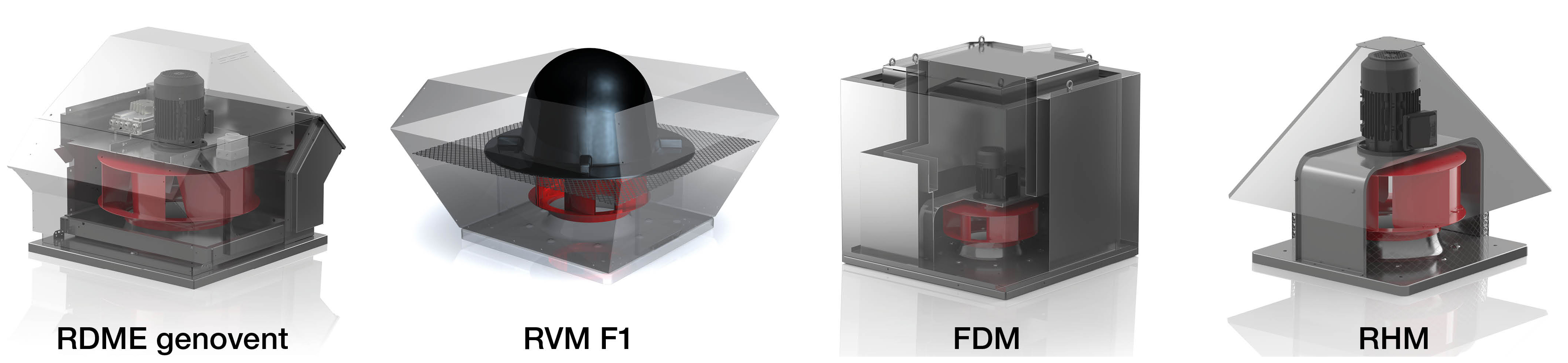

As a premium class fan, the new RDME genovent combines the advantages of its predecessors, the RDA- and RDM genovent, with the efficiency of an optimized impeller and housing dimension.The genovent is the simplest plug and play solution when it comes to maintenance and installation.The ingenious construction makes it particularly easy to open up the fan for maintenance and inspection.Automatic outlet shutters keep snow or rain from penetrating, prevent unnecessary heat loss from the duct system and save on installing a separate shutter under the fan.In terms of construction, the RDM’s motor is separate from the exhaust airstream.Variants with up to 120 degrees media temperature are thus available for special requirements, such as for transporting exhaust air from kitchens.

The core of the new RVM ELO is the impeller with dimensions and shape designed for efficiency.It consists of six aerofoil blades and has proven itself in the centrifugal fans segment for many years.With its special shape, the blades build up equal pressure at all sections.Ultimately, the air flows around the blades better and the air flow tends less to separation.This significantly lowers pressure losses.In addition, the RVM EVO’s vertically discharging housing specially designed by us ensures ideal flow conditions in the fan.A welcome side-effect of the technology is the pleasant reduction of the noise level.But it gets even quieter: the basis of the new noiseless FDM is the RVM EVO’s efficient motor impeller unit.With a cover that reduces noise by 11 decibels, it is at the top end of the market in terms of noiselessness.The cube-shaped housing is made of galvanized sheet steel and ensures an almost loss-free vertical blow-out direction.

Planners often tender for roof fans with a horizontal blow-out direction due to structural conditions.The new RHM is the price-effective alternative precisely for this application.The convenient construction makes it particularly maintenance friendly.All you need is to remove the cover and guard and replace the motor.

Choice of appropriate motor:

Like the RDME genovent, the RVM EVO is also equipped with an asynchronous three-phase motorin accordance with high efficiency class IE2/IE3.For even higher efficiency requirements, a PM motor in accordance with IE 4 is also available in the RDME.In addition, variants with an integrated frequency converter are configurable.The FDM comes with an IE2/IE3 standard motor.For the RHM, motors up to IE 2 are configurable to start with.

The advantages lie in the concept: fans with internal rotor motors are systemically superior to systems with external rotor motors.Systems that use external rotor motors have the disadvantage of the air flow of being cut off by the motor in the impeller.In addition, IE2 and IE3 standard motors exceed the traditional voltage controllable external rotor motors in terms of efficiency.The same applies to even higher motor efficiencies.Even an impeller driven by a PM internal rotor motor exceeds the energy efficiency of systems with EC external rotor motors.A further advantage: external frequency converters do not require a special filter for driving the roof fans.Even if a service is required, motors and frequency converters can be easily replaced in a few, simple steps.

And: all models have the same basic dimensions and operating data as previous roof fans by Nicotra Gebhardt.Existing mounting devices can be quickly and easily integrated.All models now available up to an impeller size of 900 mm.