Project Description

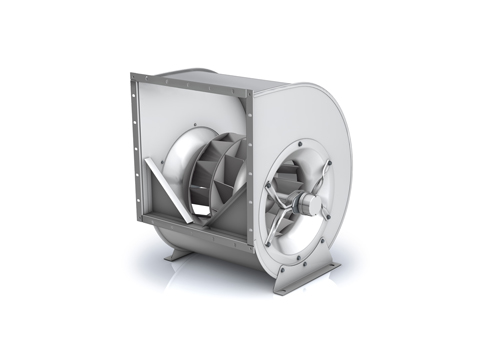

Scroll casing with backward curved hollow profile blades – double inlet

Economic, quiet and compact

Through the combination of two pioneering technologies – the aerodynamics of the rotavent impeller combined with energy efficient integral motors, Nicotra Gebhardt has developed a series of controllable direct drive centrifugal fans setting new standards for economy and quiet operation.

Your benefits:

- A highly efficient system through the use of energy optimised components: fans, motors and frequency inverters, operating together in harmonyhigh efficiency

- Low energy costs

- Low noise

- Compact and maintenance free fans

-

Flexible in its operation

Optimal aerodynamics

Low turbulance velocity for both inlet and discharge due to the large free cross section and minimal flow restraint of the impeller, an example of aerodynamics and performance of the rotavent.

Acoustics

Reduction of high frequency noise levels is just one of the advantages of the rotavent, together with optimised motors and frequency inverters. Minimal sound levels due to low blade passing frequencies from the optimised impeller geometry of the rotavent. The impeller has obliquely inclined blades with trailing edges, and the throat plate is inclined opposingly.

High efficiencies

Nicotra Gebhardt fans of the RZA rotavent range are operating at high efficiency in wide area of the fan curve

- High performance centrifugal fan RZA rotavent

- Double inlet

- Direct driven with a brushless external rotor motor

- Lap jointed scroll of galvanised sheet steel with discharge flange and bolt on multipositioned feet

- High performance impeller with 12 hollow section true airfoil blades (Size 0315/0400), with 11 backward curved laminar blades (Size 0200/-0280) inclined obliquely to the shaft axis

- Welded in position and epoxy coated

- Throat plate inclined obliquely in opposition to blade inclination

- Inlet cones matched to the impeller to reduce entry losses

- Impeller fixed to the rotor of the brushless motor in IP54 type protection, completely maintenance free, statically and dynamically balanced to DIN ISO 1940, vibration isolated mounting, ready to connect with a metal connection box

- Optimised and approved for operation with an Electronic Commutation Unit.